Magnetite

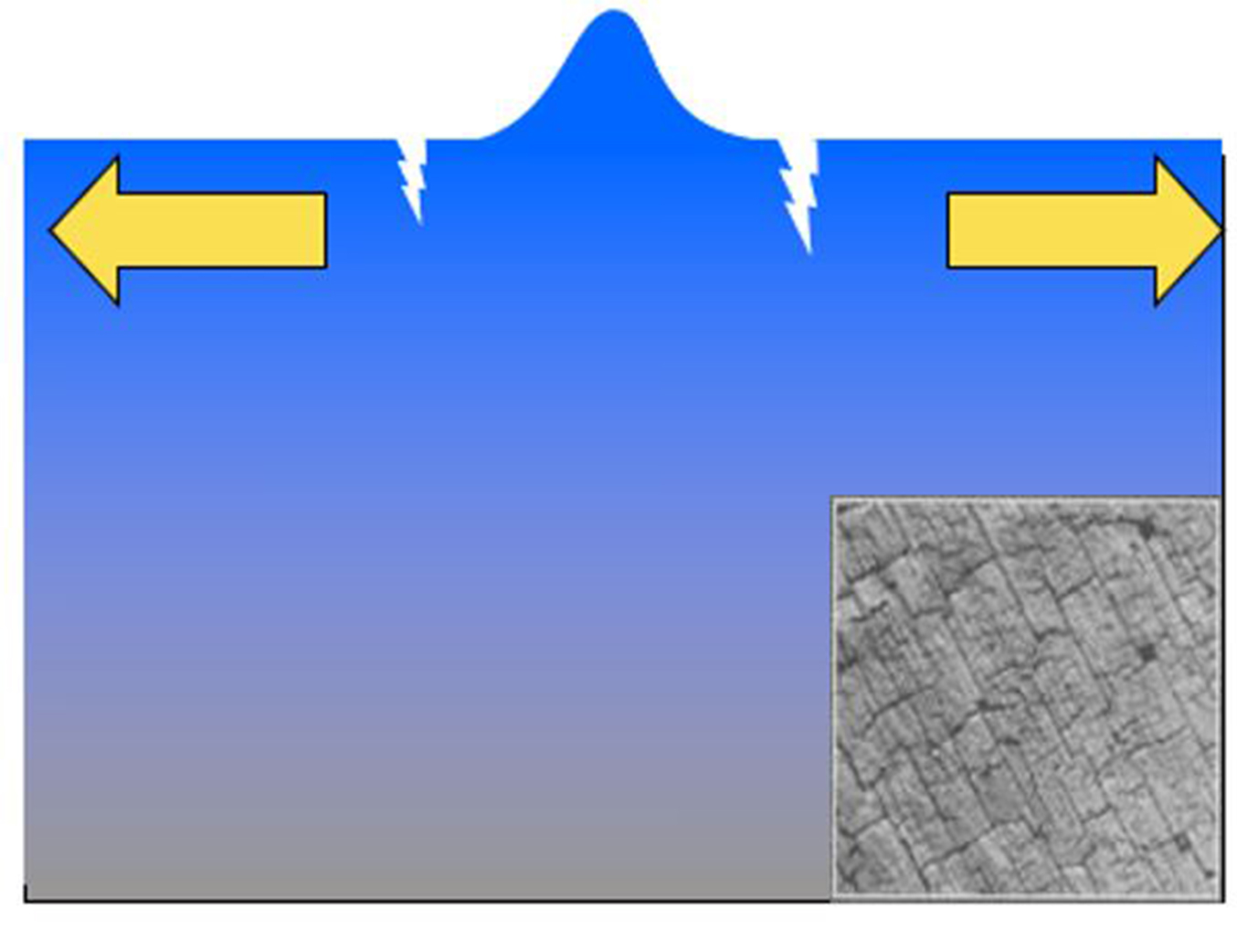

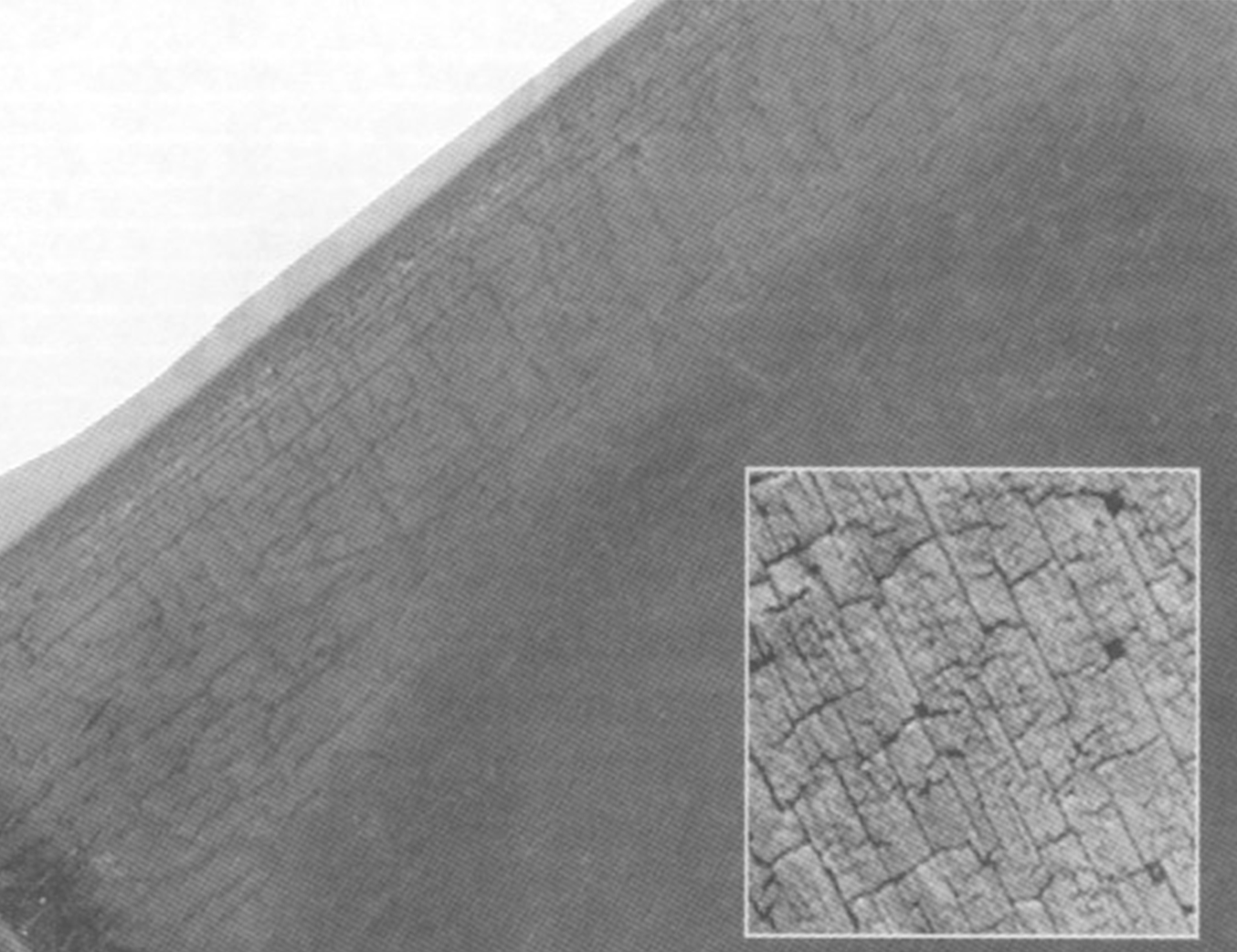

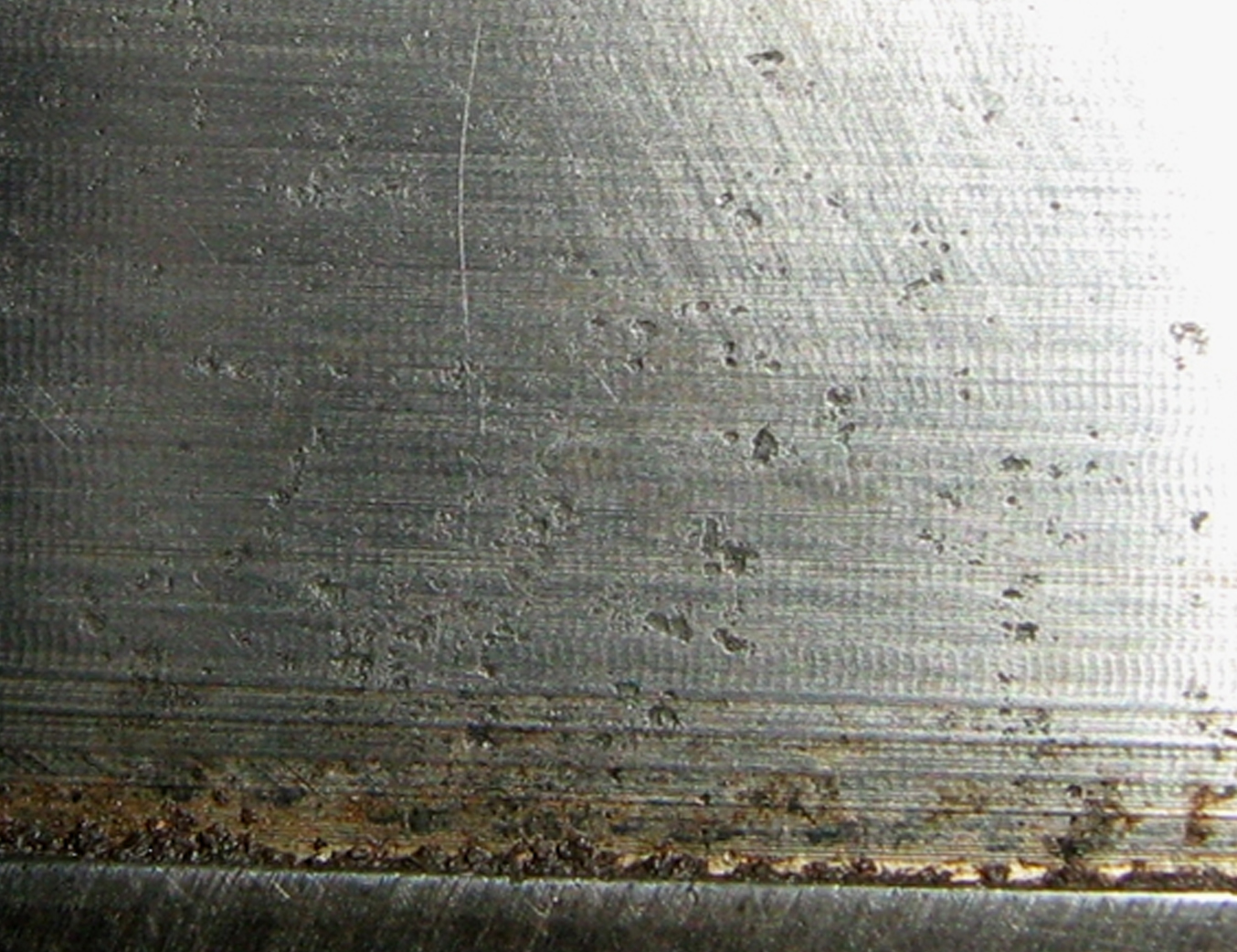

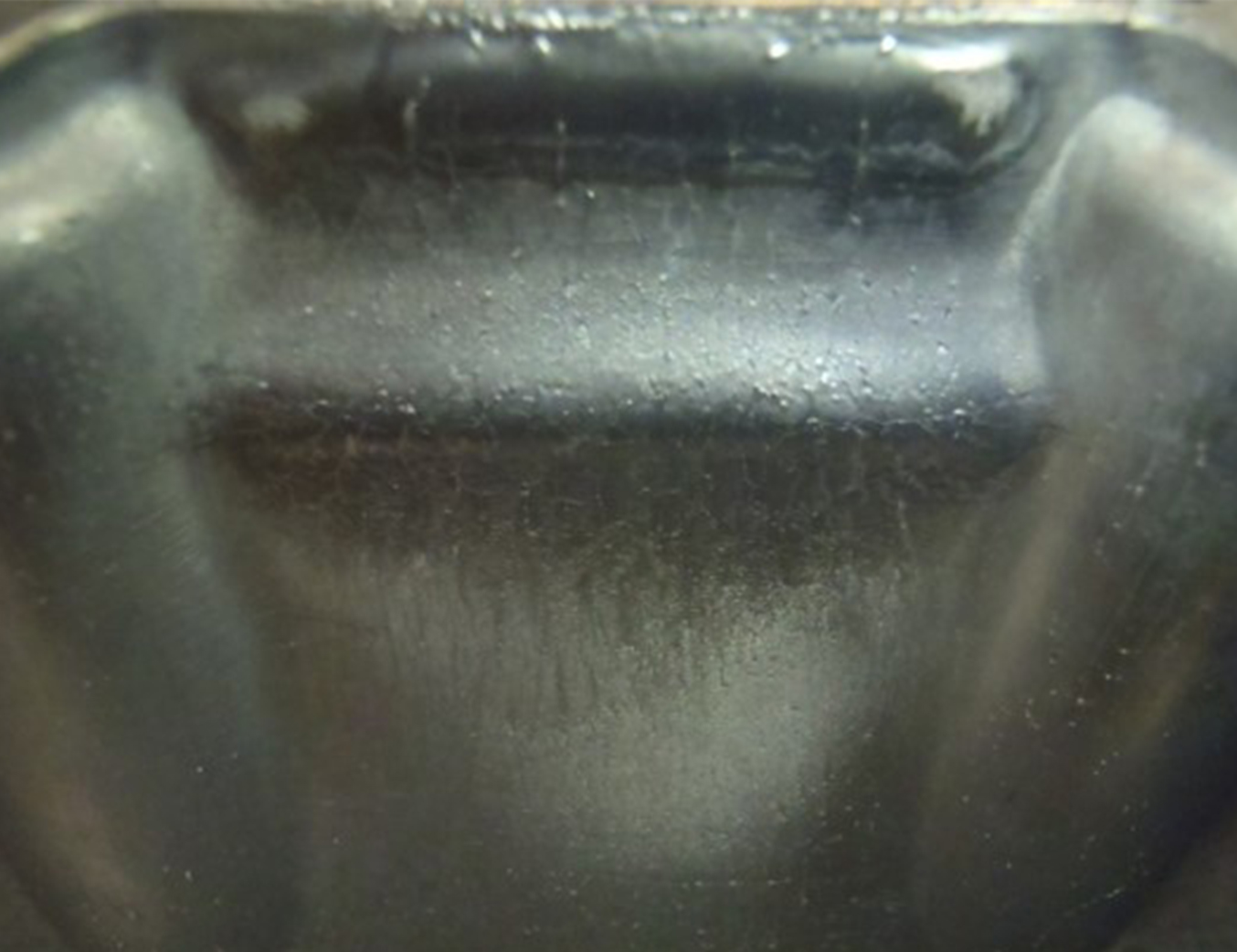

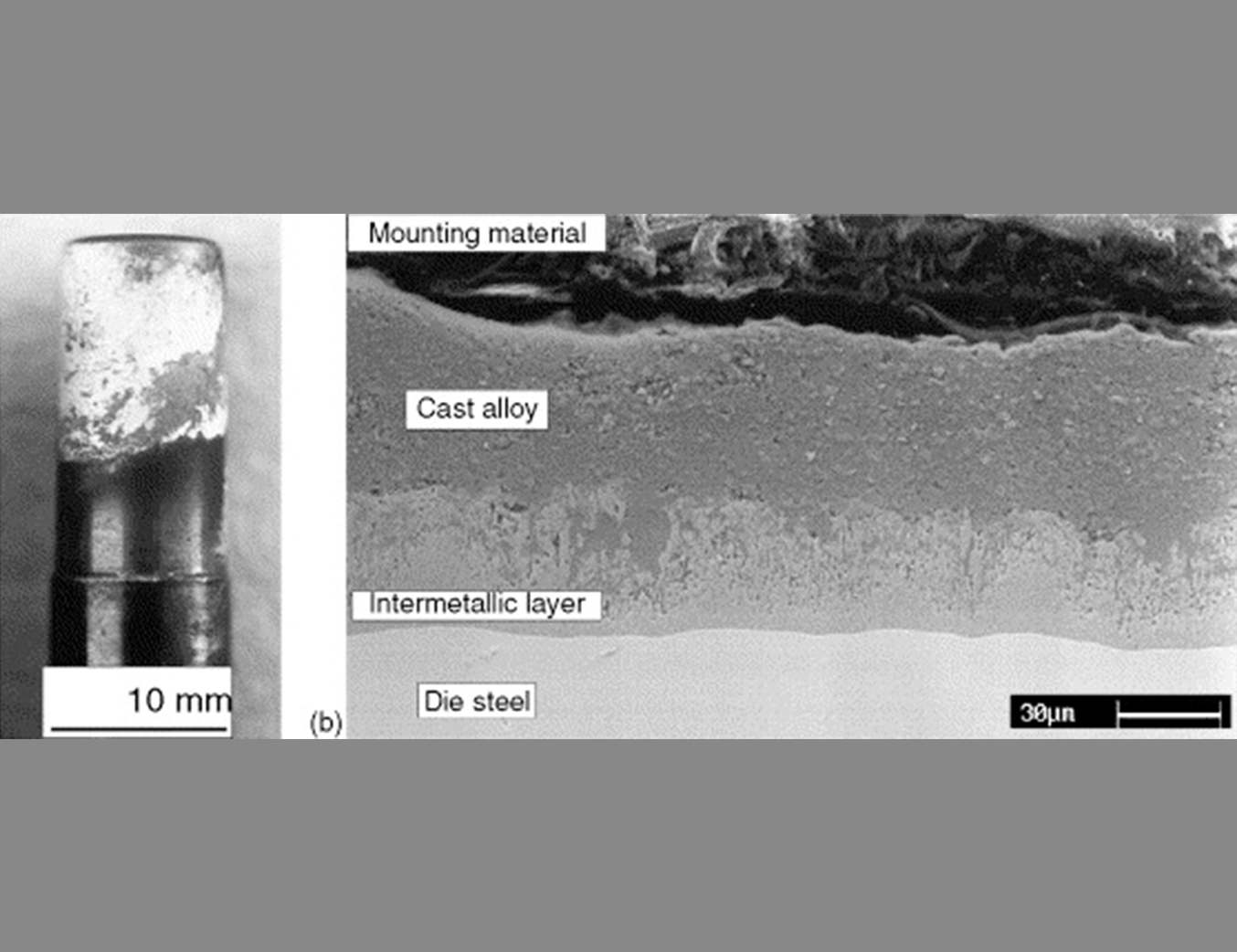

Magnetite is an advanced oxidation process which produces thin oxide layer (Fe3O4) on the surface of the die. In Die Casting process, this oxide layer acts as a barrier between the Die steel and liquid Aluminum. Also this oxide layer helps to retain the lubricant (Die coat) on the die surface. Magnetite layer also provides better protection from Soldering.

Benefits from Prolong Surface Techniks:

Reducing tensile stress

Prolonged Heat check initiation

Reducing the downtime

Prolonging the preventive maintenance

Increased Corrosion/ Corrosion pitting resistance

Improved Wear Resistance

Prolonging Soldering effect

Easier component ejection

MAGNETITE process is recommended for new dies where Soldering & Erosion are the predominant failure modes and can be repeated if necessary based on the die behaviour.It increases the die life case to case and in general, it increases 40-60% of die life. Erosion and soldering resistance increases significantly. Slight influence in Heat check resistance due to increase in compressive strength of the surface.