MaxxShot

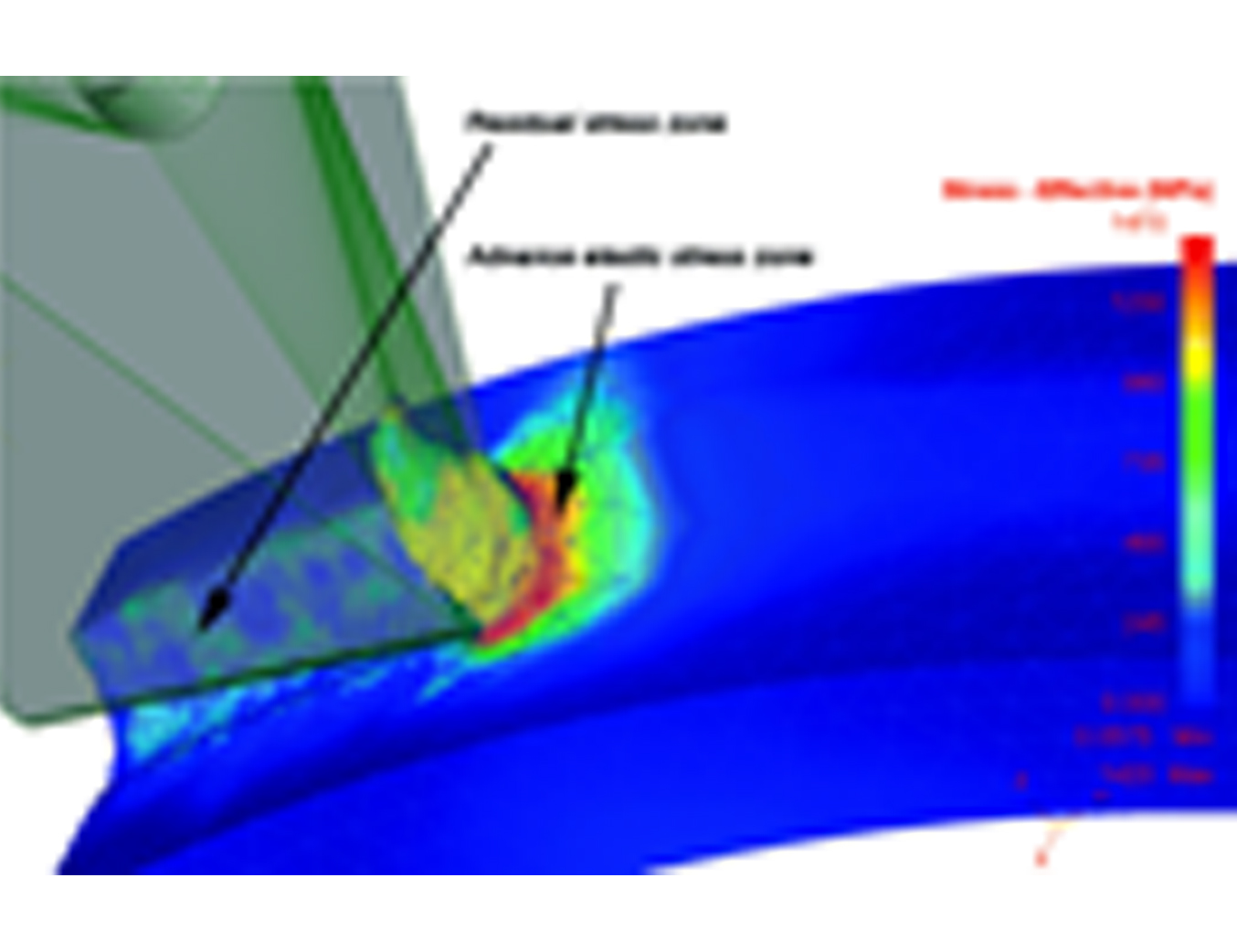

Maxxshot is a specialized surface treatment process to induce compressive residual stress on the surface & sub surface, thereby increasing the Heat Check Resistance, avoiding Pitting Corrosion & Stress Corrosion Cracking (SCC).

MaxxShot Plus

MaxxShot Plus is a Duplex process in which, MaxxShot is carried out incombination with a superior controlled Nitriding process (Tufftride) followed bysecondary surface preparation and Magnetite. MaxxShot Plus with higher Nitriding case depth increases the life of press forgingdies significantly.

Heat Checking is a tensile stress fatigue which is influenced by following factors:

Hardness, Toughness & Hot yield strength of Tool Steel

Residual Tensile Stress induced due to hard machining

Surface deterioration due to machining challenges

EDM surface defects

Inadequate Die maintenance

Casting process parameter

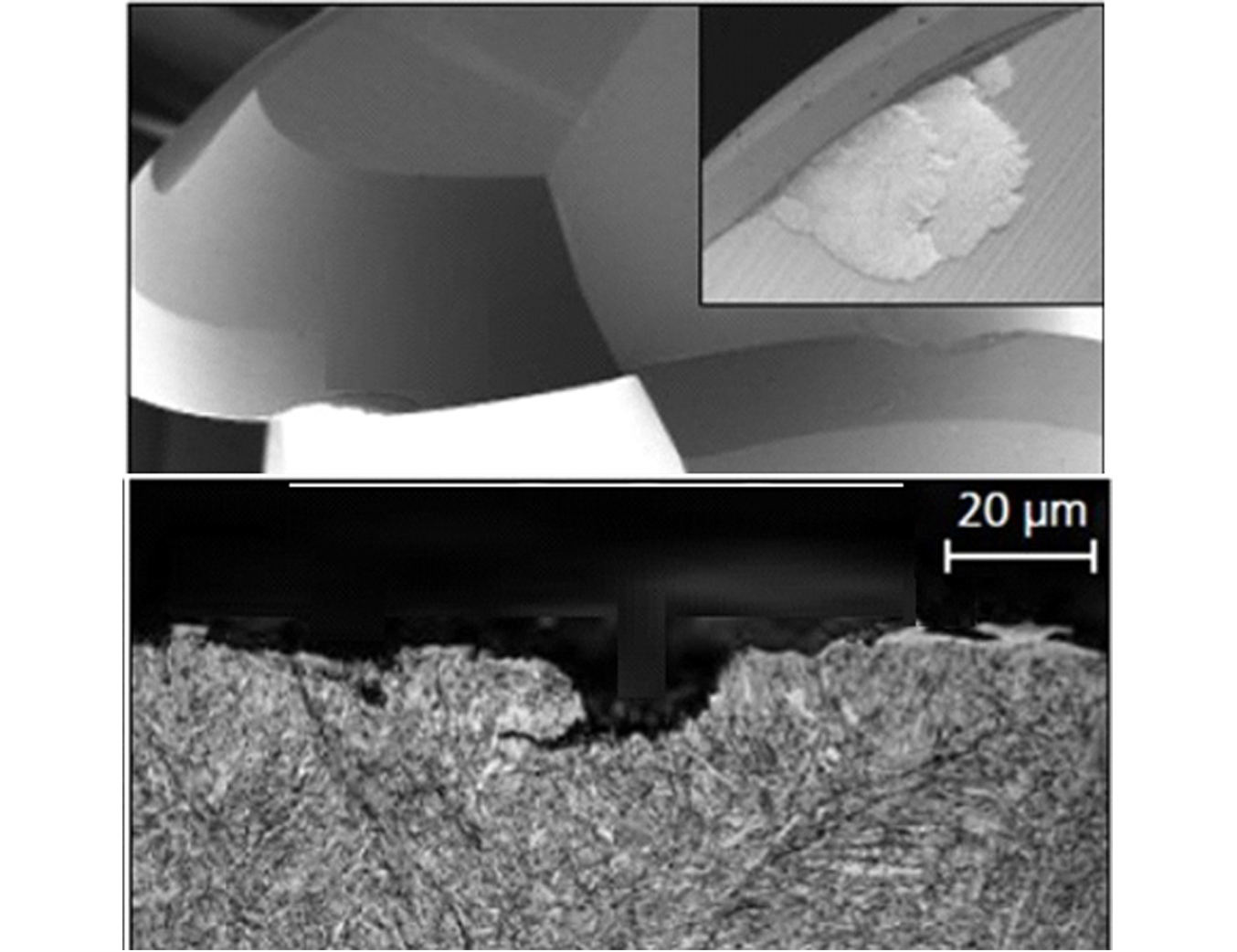

MaxxShot is a highly controlled bombardment process which creates a reactive action from the material core thus resulting in a beneficial surface & sub surface compressive residual stress. MaxxShot process includes Stress tempering, Removing EDM layer & Correcting Surface deterioration, Inducing Compressive Stress & Magnetite Coating.

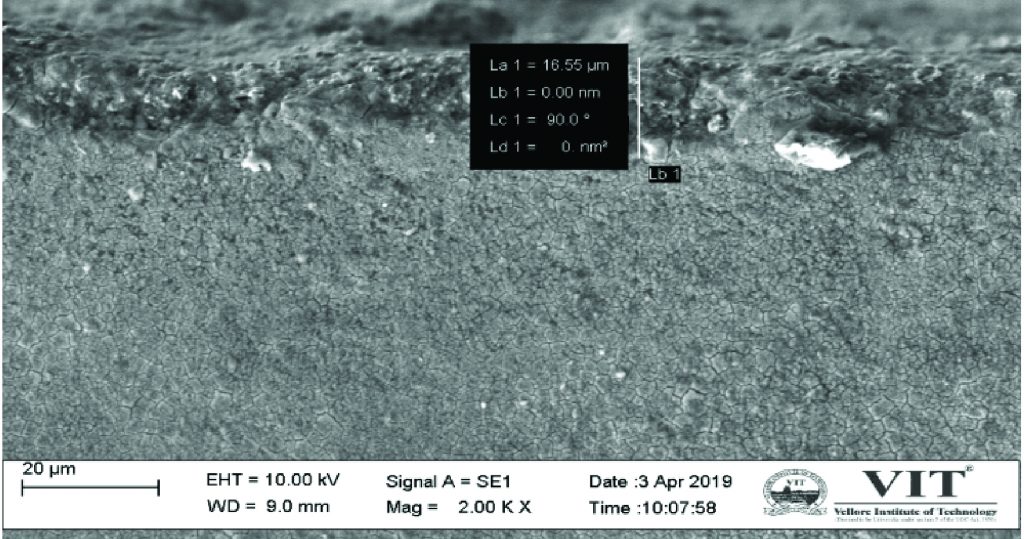

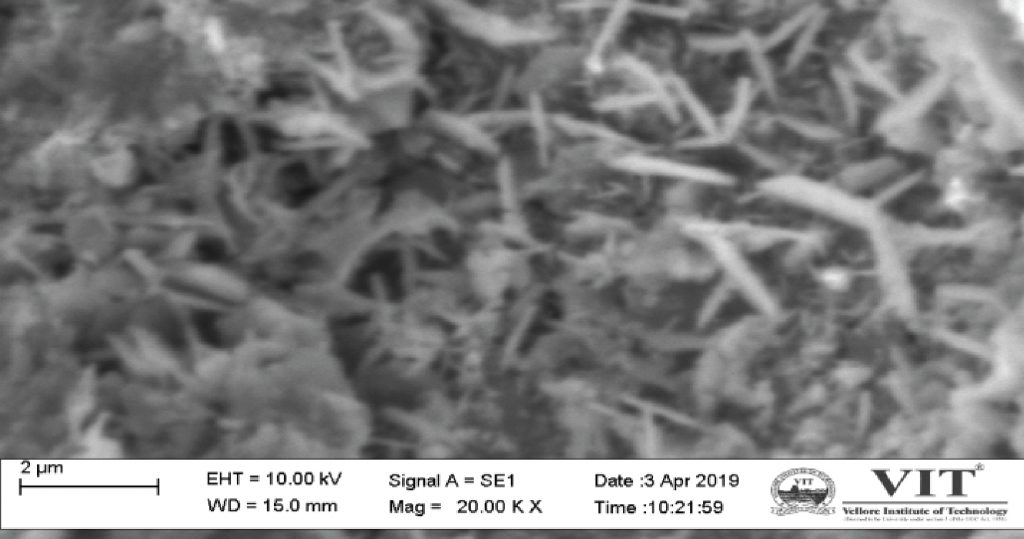

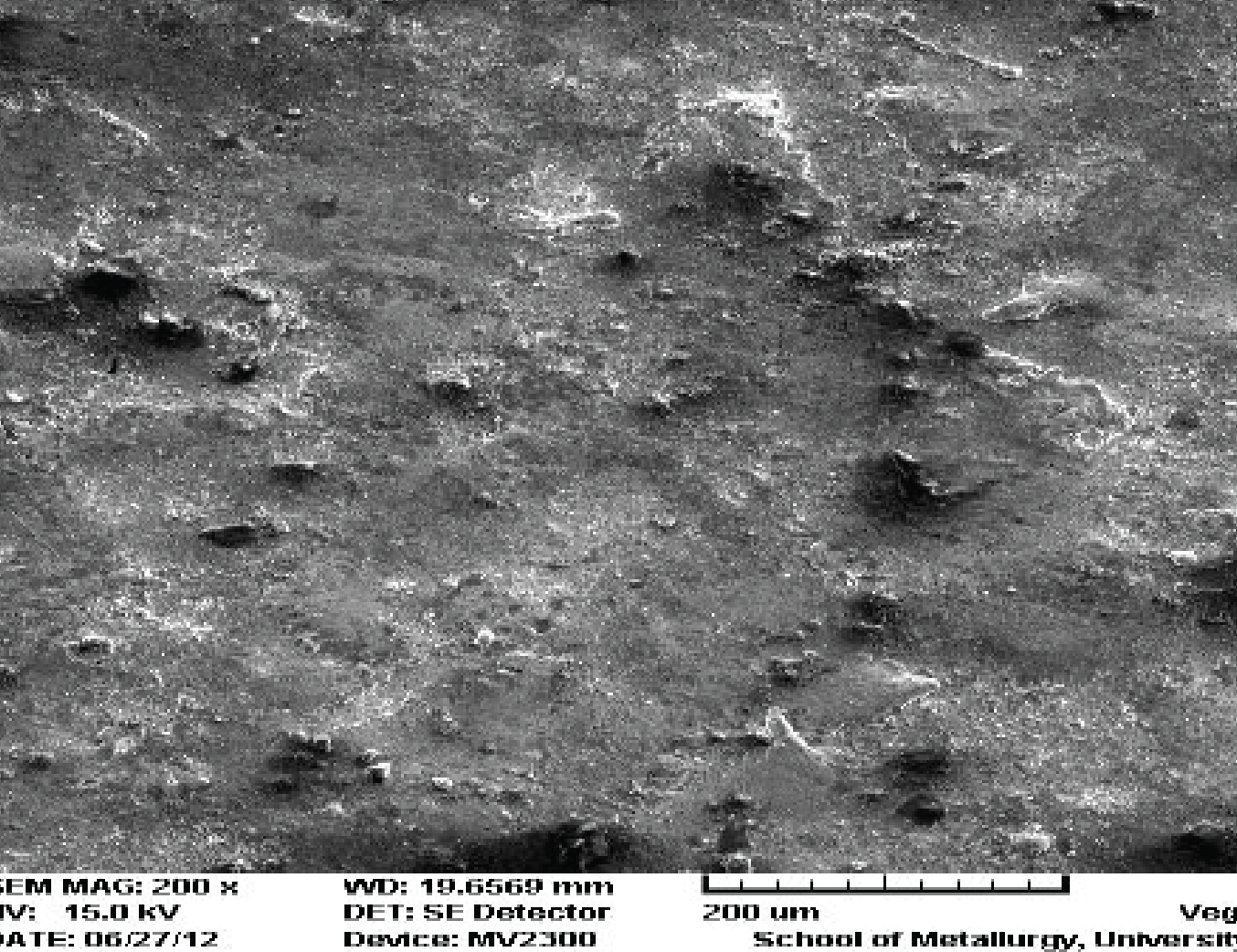

SEM Image of Magnetite Layer