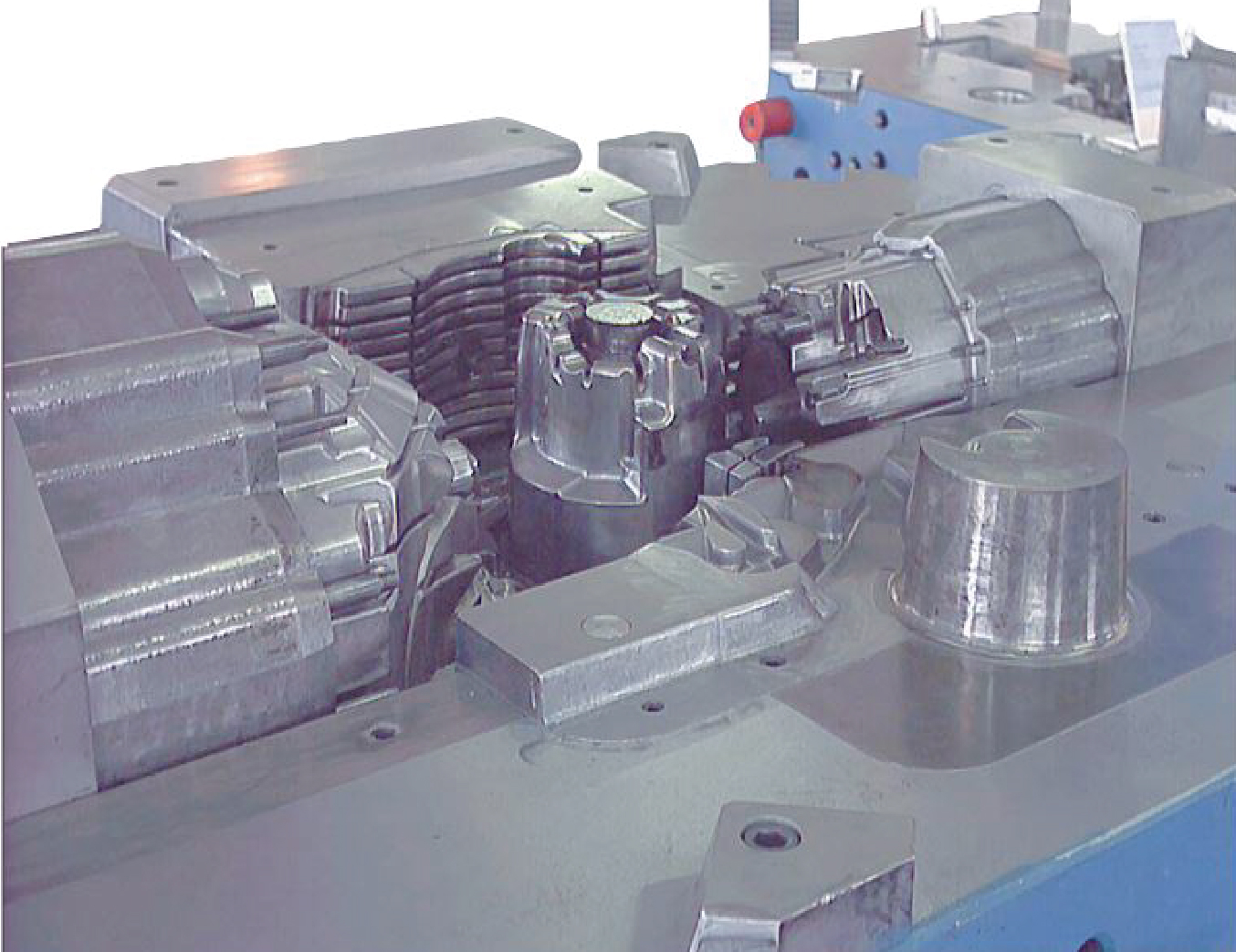

Stress Tempering

Stress Tempering is a process to reduce or eliminate the tensile stresses present on the surface of a die after it has been in production for a period of time, thereby enhancing die life. This process is also commonly referred to as stress relieving throughout the industry.

Recommended cases for Stress tempering:

After any EDM work (mandatory).

After final machining(mandatory).

After weld repair of a finished die (mandatory).

Prior to weld repair of a finished die (desired).

After the die has been in service for a predetermined number of shots (mandatory).

Stress tempering should be performed on die casting dies after the initial die sampling and then on a scheduled basis, depending on the severity of heat checking experienced. Generally, it is recommended that stress tempering be performed after the running-in period of the die and then after 1000-2000 and 5,000-10,000 shots. The procedure is then repeated for each additional 10,000-20,000 shots, so long as the die exhibits only minor amounts of heat checking.